Product Information

High Speed Dispenser CPD-G2

Feature

EnableFurther Small Components by Jet Dispense Head

Achieves Top Class Dispensing Tact Time

Continues High Precision Dispensing by Reliable Structure

Meets Wider Dispensing Needs with Variety Options

SPECIFICATIONS

| PCB Size | 50×50~460×360mm (D-model) 50×50~510×460mm (L-model) |

| Dispense Method | Piezo Type Jet, Air Pulse |

| Dispense Head | 1~3 Head(s) |

| Dot(s)/shot | 1 dot/shot (Jet Head), 1~4 dot(s)/shot (Air Head) |

| Dispense Speed (at Optimum Condition) |

0.05sec/shot (Jet Head) 0.07sec/shot (Air Head) |

| Accuracy | ±50μm |

| Rotation | ±90°, (±180°: Option) |

| Nozzle | 1~4 dot(s), Center Stopper, Non-Contact, etc. |

| Syringe | 30cc (10cc, 20c : Using Adapter) |

| Conveyor | Automatic Width Adjustment |

| OS | Windows10 |

| Operation | Touch Panel |

| Air Supply | 0.5MPa Clean and Dry Air (40Nl/min) |

| Power Supply | Single phase 200, 220V, 3.0kVA |

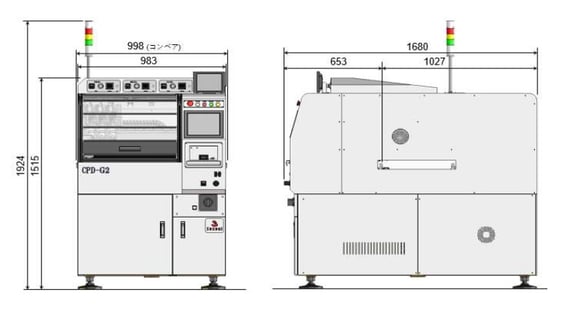

Size

Lead-Free N2 Reflow Oven SRF8225NⅡ

Feature

Low Nitrogen Consumption

Powerful Heating / Cooling Capability

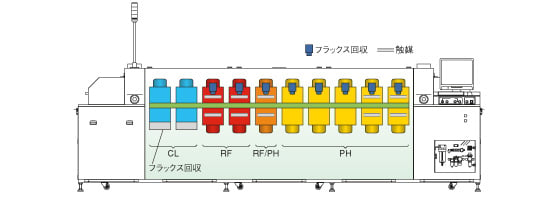

New System for Countermeasure against Flux

SPECIFICATIONS

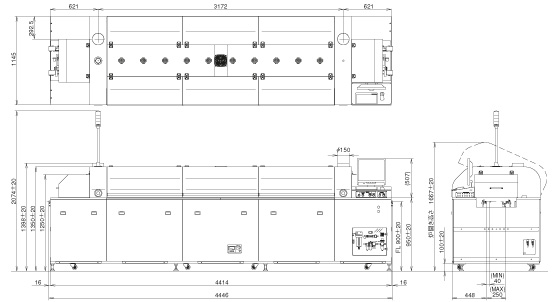

| Dimensions | 4,446(L)×1,090(W)×1,350(H)mm (Excluding Projection) |

| Conveyor Height | 900±30mm |

| PCB Size | 40×50~250×330mm Mounted component height: ±25mm |

| Zone | Heating: 8 zones Cooling: 2 zones |

| PCB Holding | 3mm from PCB edge |

| Controller | PLC (Main) PC (Display, Operation, and Profiler) |

| Utilities | Air Supply : 0.5MPa Clean and Dry Air N2 Gas Supply: 0.5MPa (max: 150 /min.) |

| Power Supply | 3 phases 200V±10V 50/60Hz 35kVA |

| Weight | Approx. 1,500kg |

Zone Configuration

Size

LED flip-chip mounting device BDM-1000

Features

Flip-chip mounting through innovative direct wafer

Next generation rapid productivity which far outperforms existing bonders

First ACP batch wafer transfer system in the world

Mini LED compatible

Self-alignment control through optimization of ACP membran